Scientists discover astonishing self-healing metal phenomenon through cold welding in nano-scale experiments, revolutionising engineering possibilities and shedding light on fatigue failure in materials science.

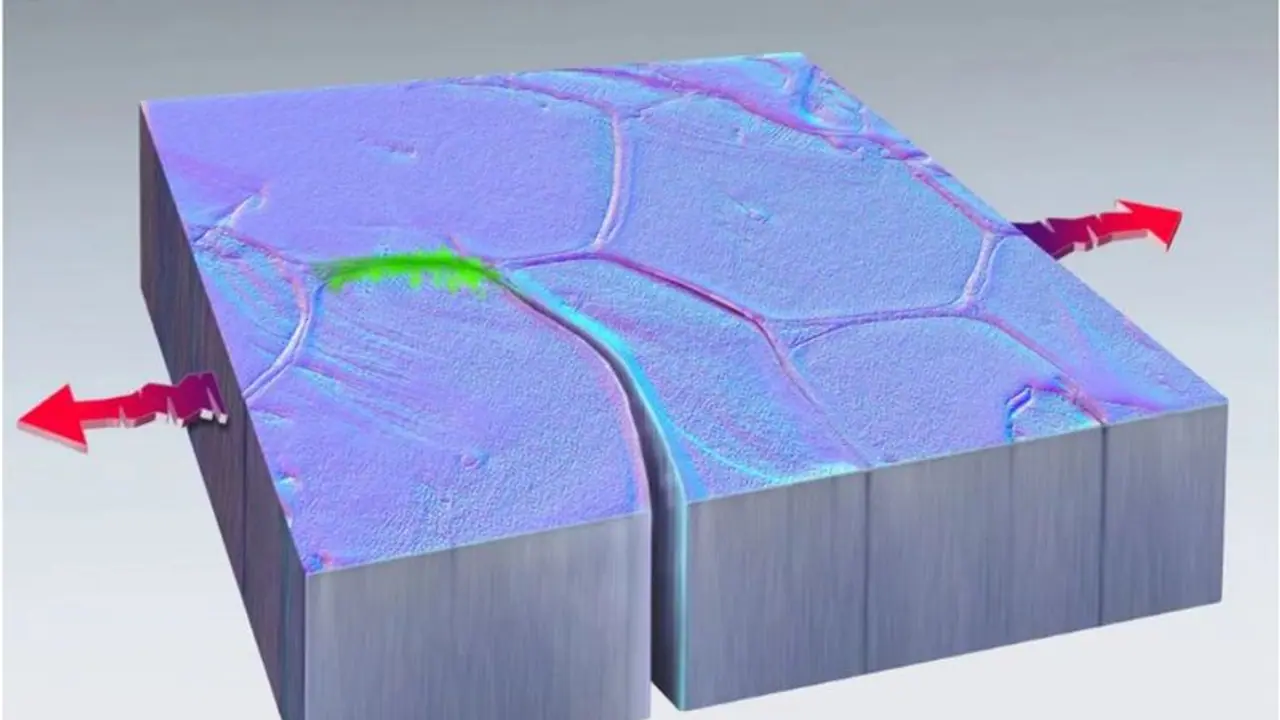

Scientists from Sandia National Laboratories and Texas A&M University have made a stunning discovery, witnessing a metal healing itself during an experiment. The researchers were conducting resilience tests on the metal, using a specialied transmission electron microscope technique to repeatedly pull the ends of the metal 200 times per second. Initially, a crack formed and spread, but after approximately 40 minutes, the metal miraculously fused back together. This remarkable phenomenon has been termed "cold welding."

The self-healing of the metal occurred at an ultra-small scale in a 40-nanometer-thick piece of platinum that was suspended in a vacuum. The breakthrough observation has the potential to revolutionize engineering and has been documented in the journal Nature.

According to Brad Boyce, a materials scientist from Sandia National Laboratories, cold welding is a metallurgical process that involves the reformation of atomic bonds when two smooth and clean metal surfaces are brought together. However, unlike the visible self-healing in the Terminator movie, this process takes place at the nanoscale and remains beyond human perception and control.

"The cold welding process is a metallurgical process that is known to occur when two relatively smooth and clean surfaces of metal are brought together to reform atomic bonds. Unlike the self-healing robots in the 'Terminator' movie, this process is not visible at the human scale. It occurs at the nanoscale, and we have yet to be able to control the process," Boyce said.

The experiments involved metal pieces that were around 40 nanometers thick and a few micrometers wide. While the self-healing was observed in platinum and copper, simulations suggest that this property may also exist in other metals, including alloys like steel.

This newfound understanding could lead to alternative material design strategies and engineering approaches to mitigate fatigue failure. It may also shed light on fatigue-related issues in existing structures, enhancing our ability to interpret and predict such failures.

In the past, scientists have developed self-healing materials, mainly focusing on plastics. A co-author of the study, Michael Demkowicz, a materials science and engineering professor at Texas A&M University, had predicted self-healing in metals a decade ago. Under certain conditions, subjecting metal to stress that would typically worsen fatigue-related cracks could instead trigger self-healing.

Despite this groundbreaking discovery, tangible applications of the findings may take another decade to develop, according to Demkowicz. While the comparison to the sci-fi T-1000 robot from the Terminator movie is not quite accurate, the concept resembles the idea of making metal behave more like organic tissue capable of healing its own wounds, similar to the fictional Cylon technology depicted in Battlestar Galactica.

The experiments were conducted in a specific environment using an electron microscope, leaving a question about whether the self-healing process occurs in the air, not just in the vacuum of the microscope. Nevertheless, this discovery carries significant implications for fatigue in space vehicles and subsurface cracks that are not exposed to the atmosphere.