India's solar module segment faces a major oversupply, prompting calls to shift from aggressive expansion to backward integration. A report by Elara Securities warns of a supply-demand mismatch and urges focus on upstream manufacturing.

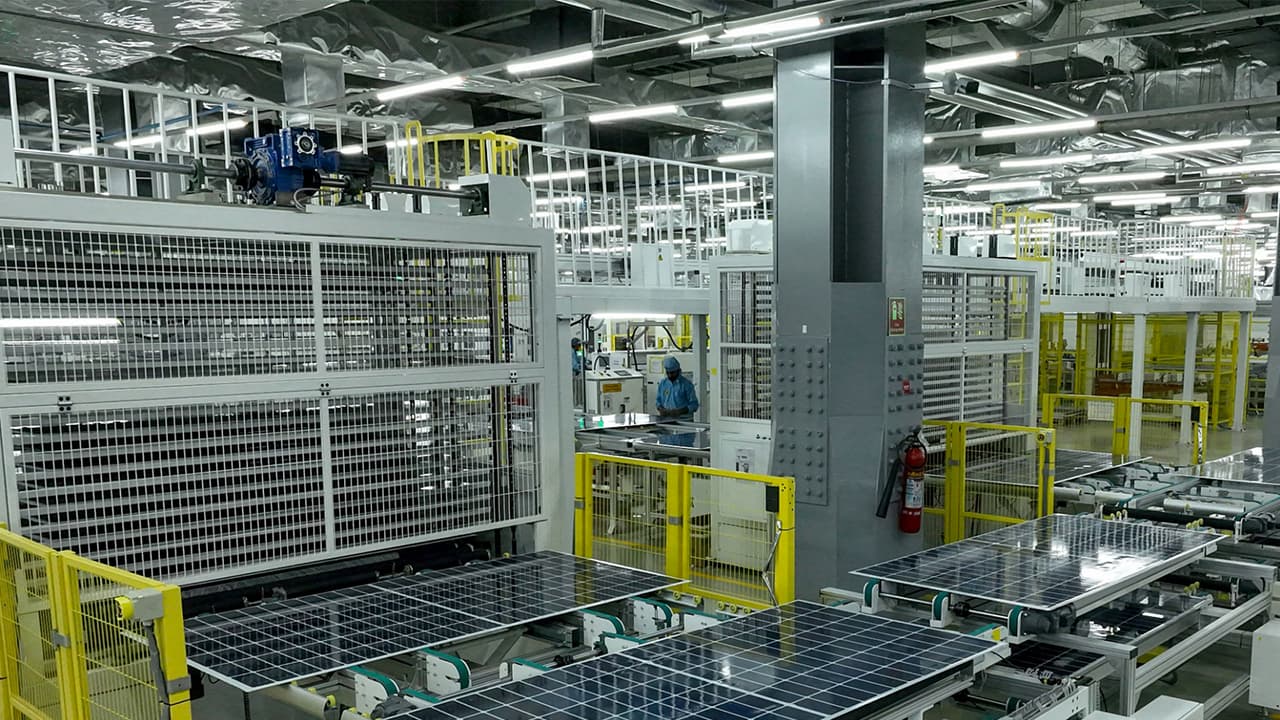

Amid rising oversupply in the solar module segment in India, the industry should shift its focus from rapid capacity addition to backward integration and manufacturing maturity, as upstream segments such as cells, wafers, ingots and polysilicon remain relatively underdeveloped, according to a report by Elara Securities.

The report noted that oversupply in modules is outstripping near-term demand, pivoting India's solar module industry away from aggressive expansion towards strengthening the upstream value chain.

Overcapacity Concerns and Market Pressures

While module manufacturing has scaled up significantly, upstream segments continue to lag, creating structural imbalances within the ecosystem.

It stated, "Oversupply in module outstrips near term demand, pivoting India's solar module industry, from rapid capacity addition to backward integration and manufacturing maturity"

India's solar manufacturing capacity has expanded rapidly in recent years. Module capacity has reached around 144GW operational and is projected to touch approximately 180GW by FY30. In comparison, cell capacity stands at around 23.4GW, according to data cited from the Ministry of New and Renewable Energy (MNRE).

The report highlighted that annual solar installations in India may reach only 45-50GW, while module output stands at 60-65GW, resulting in a clear supply-demand mismatch and overcapacity concerns in the module segment.

US tariffs have further curbed exports, leading to excess supply being diverted into the domestic market. This has added pressure on smaller and pure-play module manufacturers, increasing the likelihood of consolidation in the sector.

Policy Push and Path to Sustainability

The report also pointed out that policy support could reshape the demand outlook for upstream segments. The ALMM List-II, which will include cells from June 2026, along with mandates for domestic cells, is expected to spike demand for locally manufactured cells.

Manufacturers that build and stabilise large-scale cell capacity ahead of peers, potentially before FY28, are likely to benefit from the policy push and improved demand visibility.

The report highlighted that while India's solar module capacity has surged, concerns around overcapacity and supply-demand mismatch remain significant. It stressed that the industry's next phase of growth should be driven by deeper integration across the value chain and strengthening of upstream manufacturing capabilities to ensure long-term sustainability.

(Except for the headline, this story has not been edited by Asianet Newsable English staff and is published from a syndicated feed.)